The Technology, Providers, Ethical, Social, Regulatory Implications

Quick links

What is a 3D Printer? | 3D Printer Comparisons | Different Printing Techniques | Regulatory, Ethical and Social Issues |

Case Study [FILMED INTERVIEW by C Greenwood]: Are We Ready For 3D Printing Now? |

3D Printing Overtakes Traditional Manufacturing Methods | Company Specifics: Kodak versus 3D Printing | How does Kodak Support 3D Printing? | Kodak Embraces Change | Speculative Risks | Recommendations |

3D Printers to Suit Every User's Needs | Regulatory, Ethical, and Social Summary Industrial and Manufacturing Use | So Is New Zealand Ready to Accept 3D Printing? | References

What is a 3D Printer?

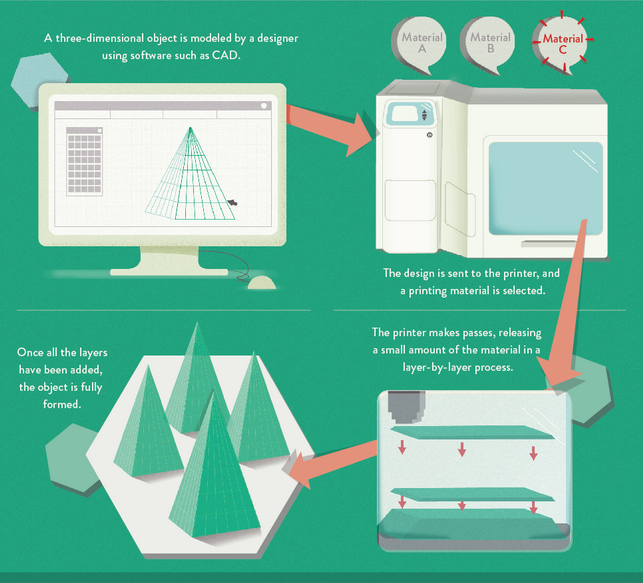

3D Printing, known as additive or subtractive manufacturing, is a process of making 3 dimensional solid objects from a digital model starting with Computer Aided Design (CAD) software.

Additive printing is created by laying down successive layers of material. The file created by a CAD is created with a 3D modelling programme or scanned into a 3D modelling programme with a 3D scanner. To get from this digital file into instructions that the 3D printer understands; software then slices the design into hundreds or thousands of horizontal layers.

The 3D printer reads this file, and proceeds to create each layer exactly to specification. As the layers are created, they blend together with no hint of the layering visible, resulting in a one three dimensional object. Subtractive methods take layers away - Lisa Harouni speaks more in depth of how the additive and subtractive methods are devised http://www.ted.com/talks/lang/en/lisa_harouni_a_primer_on_3d_printing.html

3D printing has been used in an industrial setting for approximately 30 years. Industrial 3D printers tend to be very large and very expensive, but at the same time they are a lot faster than commercial printers. Some industrial printers can print with multiple nozzles at the same time, or even use metal (more on that later). For the most part, industrial printers are nearly always used for rapid prototyping (usually by architects, automakers), but sometimes 3D printed objects — especially in the case of metal objects — are used in final products. In the meantime consumer- and small business-oriented 3D printing is only just taking off, mostly thanks to the MakerBot and RepRaps http://www.extremetech.com/extreme/115503-what-is-3d-printing

|

| Pictured: The MakerBot 3D Printer |

The MakerBot is a personal 3D printer, with single or dual extrusion (2-color printing)--and a bigger printing footprint, giving you the superpower to print things BIG! It is valued at $1,749.00

USD

. This can be purchased directly from their site,

http://www.store.makerbot.com/replicator.html

.

“RepRap

was the first of the low-cost 3D printers, and the RepRap Project started the open-source 3D printer revolution. It has become the most widely-used 3D printer among the global members of the Maker Community”

http://www.reprap.org/wiki/RepRap

.

|

| Pictured: The ReRap low cost 3D Printer |

Its successor, known as the RapMan

Ultimate Dual Head 3D Printer with TurboCAD Deluxe 18,

is available to purchase here at,

http://www.amazon.com/RapMan-Ultimate-3D-Printer-turboCAD/dp/B005OSFP0I/ref=sr_1_2?s=pc&ie=UTF8&qid=1346805094&sr=1-2&keywords=3d+printer. Its purchase price is USD 1,699.00.

|

| Pictured: The RapMan Ultimate3D Printer |

The world’s smallest 3D printer called the 3D Micro Printer was invented by Klaus Stadlmann from

Vienna University of Technology (TU Vienna).

“

…a printing device has now been developed, which is much smaller, lighter and cheaper than ordinary 3D-printers. With this kind of printer, everyone could produce small, tailor-made 3D-objects at home, using building plans from the internet – and this could save money for expensive custom-built spare parts.

Several scientific fields have to come together, to design a 3D-printer. The device was assembled by mechanical engineers in the research group of Professor Jürgen Stampfl, but also the chemical research by the team of Professor Robert Liska was of crucial importance: first, chemists have to determine which special kinds of synthetic material can be used for printing” http://www.ted.com/talks/lang/en/klaus_stadlmann_the_world_s_smallest_3d_printer.html

Additionally, Surgeon - Anthony Atala demonstrated an early-stage experiment that could someday solve the organ-donor problem: a 3D printer that uses living cells to output a transplantable kidney. Using similar technology, Dr. Atala's young patient Luke Massella received an engineered bladder 10 years ago

http://www.ted.com/talks/lang/en/klaus_stadlmann_the_world_s_smallest_3d_printer.html

.

Atala explains in depth,

Atala explains in depth,

- "We actually take a very small piece of the bladder from the patient -- less than half the size of a postage stamp. We then grow the cells outside the body, take the scaffold, coat the scaffold with the cells -- the patient's own cells, two different cell types. We then put it in this oven-like device. It has the same conditions as the human body -- 37 degrees " http://www.ted.com/talks/anthony_atala_printing_a_human_kidney.html

The only desktop 3D printers available today are by Objet. They are a multi-national company with office world-wide. They have won many awards for their innovative 3D printers. The Objet Connex

™ line of multi-material 3D printers features the world’s only technology to simultaneously jet 2 materials. With this, users can print many different materials into a single part and print various mixed parts on the same build tray. Users can also create advanced composite materials, or Digital Materials™ featuring unique mechanical and thermal properties.

Objet’s 3D printers are available in a range of form-factors, from cost-effective desktop 3D printers’ ideal for entry-level professionals, all the way to industrial-scale multi-material machines for front-line designers and top manufacturers. Objet’s 3D printers feature the industry’s highest-resolution 3D printing quality, based on 16-micron (0.0006 in.) super-thin layering, wide material versatility, office friendliness and ease of operation

http://objet.com/company/about

.

A full comprehensive list of 3D printers, attributes, performance, prices, and links can be viewed at

http://www.additive3d.com/3dpr_cht.htm

Depending on the material used, how many colours you want, the resolution you require, and how much money you’re willing to pay, there are at least five popular 3D printing methods to choose from. Some are very similar, but some are really rather crazy (or brilliant).

- Fused deposition modelling – The most common 3D printing method is fused deposition modelling (FDM). The raw material with this process is a spool of plastic or metal wire which is melted and placed by the printer’s nozzle. It quickly hardens, and then the next layer can be added. As far as commercial printers are concerned (like the MakerBot), FDM mostly uses plastic wire (filament) and is usually called “thermoplastic deposition” in layman’s terms. Metal wire melting methods are known as electron beam melting (EBM).

- Inkjet printing — Using special inks (resins and binders) it’s possible to build up a 3D model using a device that’s very similar to a home or office inkjet printer. Layer upon layer of resin and binder are added until an object is created. This is the only 3D printing process that allows for custom colours.

- Selective laser sintering – Sintering is the process of creating solid objects from powders, and in the case of selective laser sintering (SLS) the powder can be metal, plastic, ceramic, or glass. Basically, SLS uses a pulsed laser to “draw” the desired cross-section. The powder fuses, and then then the laser forms the next layer on top. This is very much an industrial method, as it requires a rather strong laser.

- Digital light processing – With DLP (yes, the same technology behind DLP projectors), a vat of liquid polymer is turned into a very strong solid by exposing it to light. Very high accuracy/resolution can be achieved with this technique — and again, this is an industrial method. Stereolithography is similar to DLP manufacturing, but a lot more expensive.

- The others – Finally, there are a few 3D printing techniques that aren’t used extensively, but could be in the future. Resin can be cured using LEDs (similar to the DLP approach); 2-photon photopolymerization can be used to create ultra-small 3D-printed features; laminated object manufacturing uses bits of paper or card stuck together that are then cut out using a laser.

Advances in technology, coupled with more affordable 3D printers becoming available in the market, will see this technology more readily available to a wider variety of users. This will undoubtedly raise legal and ethical questions as to what the technology can be used for as it becomes more widely understood and it’s capabilities become apparent.

Eyebrows will be raised when matters such as copyright and trademark infringements come into play. Conservationists may even begin to challenge the impact of all the plastic being introduced onto the planet.

The question of intellectual property has been raised. We could one day see piracy lawsuits directed at people who have illegally downloaded gearboxes or bookcases, and or internet usage governed or cut off as a result

http://techcrunch.com/2012/08/26/the-next-battle-for-internet-freedom-could-be-over-3d-printing/

. What has happened to the music and film industries could happen all over again to manufacturing http://www.telegraph.co.uk/technology/news/8666516/3D-printing-the-

technology-that-could-re-shape-the-world.html.

technology-that-could-re-shape-the-world.html.

In the early days of peer to peer file sharing (P2P), no one paid much attention, until the entertainment industry began to notice a drop in music sales and started making noise. When it became clear that existing regulatory mechanisms were unable to deal with P2P, governments began introducing more restrictive legislation while record companies and others began aggressive litigation against music and video downloaders – a strategy that some allege has stunted innovation in addition to being ineffective and harmful http://www.3dprinter.net/3d-printers-obsolete-firearm-controls-and-the- law

.

In an ironic case to 3D printing, the original plans to a 3D printer released as open source software have been used to duplicate a 3D printer. The creator says that the device will offer the same performance and features at a roughly 33% discount, thanks to Chinese manufacturing. That's inflamed some in the 3D printing fraternity, who take exception to the exact copying of a design without any improvement. The creator says that the technology is nothing new and insists the replica product's lower price will open up 3D printing to more hobbyists. To overcome any trademark gripes the references to the original 3D printer have been removed http://www.engadget.com/2012/08/24/tangibot-kickstarter-makerbot-clone/.

The legality for Guslick, or any individual, to own a self-made firearm has been tested in the United States by a 2008 US Supreme Court, when it was ruled in a case, District of Columbia v Heller to uphold an individual’s right to possess firearms under the American Second Amendment. The case analysed whether this decision means that people in America, who have the right to bear arms under the Second Amendment, also have the right to make arms.

Back to Top

The assumption that 3D printers will be popular in most homes by 2022 was predicted by Open Polytechnic university students (71355, Knowledge and Emerging Technologies paper, 2012, trimester 2). Furthermore, curiosity prevailed where interviews to test whether we are ready to invite 3D printers into our businesses, more specifically our homes even sooner? To test this theory a very small random sample of people were selected during a festival/market event, from a small rural community, and interviewed on the streets, or in surrounding buildings i.e. library, hall etc. Participants were asked the following:

- Do you know what a 3D printer is? - From their responses, they would be informed of what a 3D printing does, and what it is capable of making.

- Now that you know (or already know) what a 3D printer is, what would you use it for? How could it be useful in your home or work environment?

- What impact do you think it would have on society or people?

- Do you see any limitations or benefits from 3D printing?

Out of the participants there were two females (aged 40 +) and 3 males (aged 35 +). Findings recorded that one (male) out of five people knew what a 3D printer was - in depth. Two participants (female) believed the printer to be useful for replicating, fixing, or creating new toys; one (male) saw it useful for "making templates and prototypes... for special developments;" one (male) found its use in creating camping utensils and tools, and creating 3D art sculptures; one (male) saw it useful to replicate his computer and print off food.

Its impact on society saw its use as positive responses from all in addition comments ranged from: one (male) response was, "the fact that you can print anything you desire is a positive thing;" one (female) stated, "it will probably give people a different way to think.... in changing from one dimensional to three dimensional printers;"

one (male) claimed, “... there’d be like patenting issues and copyright theft and that type of thing;"

one (female) expresses concerns of printers printing off weapons and guns; and one (male) conveyed that,

"In time computer intelligence will overtake human ability. “If we create a greater than human intelligence machine, the ability for it to reproduce would be quite important… and reprap is a self replicating machine… so if you think that we’re going to create an intelligence that’s beyond human capabilities, at some stage its going to decide that it needs to reproduce and 3D printing is the, probably the most important part of its evolution in that it can reproduce itself."Finally, with regards to limitations and benefits, all participations saw nothing but benefits. One (female) respondent saw positive impacts with organ replacements, and negatives with weapon reproduction saying that it must be heavily regulated. One (female) respondent had nothing to add; one (male) participant saw costs being a obstacle, but on the positive sees these dropping over time, while one (male) participant sees it getting bigger and cheaper as time passes; the most interesting comment from, one (male) participant claimed that its reproduction ability will mean that human input will see us redundant in 3d printer creation and input. Although this was a very small sample, it would be interesting to further develop this study with a larger sample population throughout rural/urban parts of New Zealand.

Manufacturers will be able to replace their current manufacturing prototyping methods with 3D printing, and may even be able to use 3D printing as part of the manufacturing process. 3D printing is increasingly being used by large companies to replace some of their traditional manufacturing methods with cost savings of up to 70%. This is achieved through lower shipping and packaging costs related to overseas parts suppliers, less human resources involved and cheaper, and sometimes more reliable, raw materials being used.

The speed of 3D printing compared to traditional methods of manufacturing is similar to comparing a sports car’s top speed to a horse carts

http://augmentedtomorrow.com/9-benefits-3d-printing/

. Industrial 3D printers are capable of manufacturing most products in a matter of hours while current manufacturing methods can take up to several days or even weeks.

Back to Top

Back to Top

3D printing can lead to a massive cost saving. Manufacturers will not need to have warehouses filled with products -they can manufacture them according to demand, as well as on demand. Manufacturing metal and plastic objects, in particular, is usually a wasteful process with a lot of surplus material not being used. Some aircraft makers are having up to 90% of the material being cut away which is no longer useful to them. Manufacturing a similar object using 3D printing not only uses less energy but also reduces waste to a minimum. The finished 3D printed product can be up to 60% lighter compared to the machined part but still as sturdy.

A designer, Bastian Schafer, from Airbus Industries has been working on a new concept plane with other Airbus designers that would largely be printed using a hangar-sized 3D printer. Schafer says that 3D printing could not only lead to some significant cost savings, but also allow for parts that are 65% lighter than those made with traditional manufacturing methods http://www.forbes.com/sites/parmyolson/2012/07/11/airbus-explores-a-future-where-planes-are-built-with-giant-3d-printers/.

A McKinsey & Co study suggested that if a product is late to market by six months it will have lost up to 33% of its potential gross profit over its life cycle. There is increasing pressure on companies to quickly get there first in order to assure success. Most critical product design and specification decisions are made during the first 10% of the design cycle or at the conceptual stage. These decisions can affect almost 80% of the product’s total cost by establishing material selection, manufacturing techniques, and longevity of the design. It’s extremely important to make the correct decisions by evaluating different or multiple design concepts during these beginning stages. 3D printing enables manufacturers to offer first-hand input based on durable, functional ABS parts that can be produced quickly and efficiently (Stratasys, 2002).

Industrial 3D printers are been used extensively

for rapid prototyping and research purposes. Rapid prototyping is a group of

techniques used to quickly fabricate a scale model of a physical part or

assembly. In rapid manufacturing 3D printing is able to use materials that are

appropriate for final manufacture to print finished components. The advantages

of 3D printing in rapid manufacturing lie in the relatively inexpensive

production of small numbers of parts. Rapid manufacturing is a new method of

manufacturing, and it is believed by many experts that this is a "next level"

technology http://en.wikipedia.org/wiki/3D_printing.

There is an emerging consumer and on-demand use of 3D printers for a crowd manufacturing cycle that will disrupt the conventional chain of design, production, and distribution. 3D printing will do to many categories of products what MP3 did to music – but it will also do to the design and distribution of objects what Web 2.0 did to information. The current stage of 3D printing is analogous to the early 1990s when the music industry failed to foresee the disruptive impact that on-going improvements in audio compression and increasing Internet connectivity would have on its business several years later. Businesses whose products intersect with the specific applicability of 3D printing need to urgently consider how to mitigate the coming disruption

http://johnnyryan.wordpress.com/2012/03/10/crowdmanufacturing/#more-2213.

The Kodak brand is synonymous with photos. Historically it is best known for making cameras then developing and printing the images those cameras captured. Today, Kodak looks at ways to combine images and information to produce products relevant to business and the medical and scientific communities as well as retail consumers. Any colour printing process requires a colorant, a substrate, and a printing system and 3D printing technologies are no exception

http://www.kodak.com/ek/US/en/Printed_Image.htm

. Kodak has innovated and developed technologies in all of these areas.

Kodak’s involvement in the printing industry goes

back to 1912 when they acquired London company Wratten and Wainwright – a maker

of photo-materials for commercial printing

http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Impact_of_Pictures.htm. The involvement in commercial printing continues without approximately 40% of the world’s output involving Kodak technologies.

Current areas of research with particular relevance to 3D printing are polymer science, atomic scale assembly, and chemistry modelling. Polymers are substances built up by bonding together a large number of similar units – just as a 3D model is compiled in successive layers. The work in atomic scale assembly includes looking at the reactivity of different substrates, including the ability to bond to other materials. Meso scale chemistry modelling predicts the behaviour of fluids on different surfaces and is particularly useful for predicting inkjet drop spread http://www.kodak.com/ek/US/en/Material_Science.htm. The inkjet method is a common way of building 3D objects. The Objet260 Connex 3D printer is an example of this. It combines ink-jet technology with multi-material capabilities. Possible products are showcased at

http://www.youtube.com/watch?v=ZbRlDBScDz4&feature=player_embedded#.

Kodak has also been developing printable flexible substrates. In 2010 it installed the 100th FLEXCEL NX Digital Flexographic System – a platemaking solution designed to print flexible packaging materials, such as the stand-up foil pouches you see in supermarkets

http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_-_chronology/Milestones-_chronology.htm

.

Before any printing can be undertaken, an image or plan must be acquired and delivered to the printing system. Kodak has developed innovative solutions in scanning and sharing that will prove useful when embracing 3D printing. Bone pointed out that even those comfortable using technology would have difficulty creating a usable 3D scan so these technologies are vital http://www.stuff.co.nz/waikato-times/life-style/people/6987064/ Game-changer-3-D-printing.

In 2005, the company acquired a leading provider of compact computed radiography systems – OREX Computed Radiography Ltd. The technology digitally acquires x-ray images and allows them to be shared and notated http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_-_chronology/Milestones-_chronology.htm. CAD (computer-aided design) technology is also utilised medically with the Kodak Mammography CAD engine being FDA approved in 2004 (Medical devices, 2009). This technology fits in well with 3D printing as, once images are acquired, they can be used to design replacement body parts printed in a 3D printer.

Kodak showcased its expertise in the area of scanning and sharing documents in 2006 when it announced the Scan Station 100 – a system allowing office workers to store and send information without the need of a computer interface. In 2009 it increased its interest in this area by acquiring the document scanning division of vendor BÖWE BELL + HOWELL http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_-_chronology/Milestones-_chronology.htm. This expertise in computer-free scanning translates well to the replication possibilities of 3D printing. Kodak has also developed a system to protect intellectual property. It released the TRACELESS system in 2007. The system was designed to protect against counterfeiting. Invisible markers embedded in products such as tickets or documents and luxury goods labels verify authenticity to Kodak readers http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_-_chronology/Milestones-_chronology.htm. With 3D printing allowing for replication of virtually anything, such a system is vital to avoid falling foul of copyright legislation.

Kodak Embraces Change

As previously outlined, Kodak already employs many of the technologies necessary in the 3D printing process. It can utilise its own expertise at all levels of the printing process: the colorants, the substrates, and the printing processes. In addition, Kodak has the ability to acquire images and the CAD expertise to design and produce useful objects. This positions Kodak as an end-to-end supplier. Kodak can take advantage of 3D printing in two very different ways:

- As system suppliers for specific parts of the process. E.g. scanning, CAD manipulation, and/or file interpretation. Kodak is already well placed to leverage new business from those medical, commercial, and scientific enterprises already employing Kodak technologies.

- As a retailer of 3D printed products, creating objects for those unwilling or unable to engage with 3D printing technologies themselves. This builds on Kodak’s retail branding as a supplier of unique customisable gift items. It is not necessary for Kodak to actually do the printing – this can be out-sourced to third party providers (as canvas printing and ceramic printing currently are).

Both income streams fit into existing corporate structure and the company has both the people and the processes to incorporate the new technology into the existing business.

Bone supports Elley in saying that, in the short term, 3D printer use will develop as conventional printing did – with small desk-top machines for everyday jobs and large centralised systems for quality jobs http://www.stuff.co.nz/waikato-times/life-style/people/6987064/ Game-changer-3-D-printing . Kodak has built its reputation on quality so any solutions implemented must support that brand.

Kodak is currently emerging from a chapter 11 reorganisation (part of the US bankruptcy process where a trustee runs the business) so any large investment in equipment may be hard to justify http://www.usatoday.com/money/ industries/manufacturing/story/2012-07-11/kodak-reorganization/56149400/1

This section discusses the feasibility of using 3D printers. It revises the attributes of the different 3D printers and the methods used, the regulatory, ethical, and social guidelines, traditional manufacturing versus 3D manufacturing, as well as how it stacks up in the general and medical photography industry acknowledging the Kodak case study mentioned above.

3D Printers to Suit Every User's Needs

“Which is the best 3D printer? There's no such thing. The best 3D printer or rapid prototyping system is the one that meets more of your criteria than the others. All additive fabrication machines come with limitations and unknowns - some more than others” http://www.additive3d.com/3dpr_cht.htm.

Castle Island contends that the 3D Systems and Objet technologies consume a large range of materials, have fast processing with a high finishing grade, and for business use or basic production http://www.additive3d.com/3dpr_cht.htm. They are not for the average home user’s budget however.

Whether you require selective laser sintering (SLS) with thermoplastics, metal powders, and ceramic powders, to electron beam melting (EBM) using titanium alloys, or stereolithography (SLA) of photopolymer materials, to fused deposition modelling with plastics, the method and material used is relative to your desired outcome. You select the method of manufacturing, materials to make your item from, and presto, your product is supplied. Additionally, machines range in sizes from small portable versions, no bigger than a 1kg packet of Weetbix to larger systems also

http://www.ted.com/talks/lang/en/klaus_stadlmann_the_world_s_smallest_3d_printer.html

If its portability, excellence in the finished result, accuracy, speed, methods of printing, and material selection, again, these attributes must be taken into careful consideration as to what you aim to achieve. Like purchasing a computer, the faster the processing speed, or hard drive, the more you will pay. You choose what you want, to suit your needs, and your budget whether it’s for home use or manufacturing needs.

Regulatory, Ethical, and Social Summary

It is predicted that copyright and trademark infringements will come into play in the not too distant-future. Could this make or break 3D printing? It will definitely throw a spanner in the works. “While there are no real legal challenges to 3D printing now, some may come as the technology becomes more popular, Rad said. The proposed Anti-Counterfeiting Trade Agreement (ACTA), with 37 nations negotiating new intellectual property protections, could make it more legally difficult to reverse-engineer products in many countries.... leading to the inventors of the printers liable” http://computerworld.co.nz/news.nsf/technology/3d-printing-a-minefield-of-legal-challenges.

We could one day see piracy lawsuits directed at people for illegally downloading blueprints of patented items

http://techcrunch.com/2012/08/26/the-next-battle-for-internet-freedom-could-be-over-3d-printing/

.

Intellectual property means that the Government may deactivate your internet usage if pirating occurs online. This is the argument that Stop Online Piracy Act (SOPA) aim to enforce http://techcrunch.com/2012/08/26/the-next-battle-for-internet-freedom-could-be-over-3d-printing/.

Alternately, 3D printers do not require online applications or access to operate. In addition, they are relatively simple to assemble for the technologically minded therefore bypass the scrutiny and detection of online pirating http://reprapbook.appspot.com/. For this reason, the regulatory feasibility remains unpredictable.

Ethically, conservationists may challenge the impact of all the plastic being introduced onto the planet, but on the other hand they may embrace the usage of recycled plastics, glass, and other materials too. Perhaps as 3D printers become more sophisticated, the materials may utilise only that of recycled products. Imagine putting your soft drink bottles in one end and receiving a fully customised pair of shoes at the other.

In short, traditional manufacturing methods allow mass production, and require tools to produce parts (hardware driven), whereas 3D printing can customize and produce items on demand, that is software driven. This has clearly reflects a paradigm change in manufacturing.

Kodak has made success in the commercial industry, making a comeback in 2010 producing stand-up foil pouches you see in supermarkets through the 100 th

FLEXCEL NX Digital Flexographic System http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_-_chronology/Milestones-_chronology.htm

. Additionally, Kodak is making breakthroughs in the medical and scientific industries with scanning technology, under construction, that aims to scan human body organs. These predicted successes aim to reinstate Kodak’s reputation not as the copier

developer

and processor in the commercial, medical, and scientific industries. Kodak’s 3d scanning can take advantage of 3D printing for the most intricate and complex tasks. Imagine scanning and printing skin to graft burns, or cover over unsightly tattoos, or scanners so sophisticated they can scan items at distance and speed, such as aircraft in flight in search for contraband, or vehicles in pursuit. These are ground breaking ways that Kodak can engage in a 3D printer scanner copier environment. Back to Top

So, Is New Zealand Ready to Accept 3D Printing Technology?

To sum it all up - yes, New Zealand is ready for 3D printing technologies. Based on the case study notes, four out of five participants had no idea what a 3D printer was, and when they were educated on what they were and their capabilities, all participants were very aware of its limitations and legalities, as well as the huge benefits from owning one. They are also forward thinking in the sense of how 3D printing reproduction capabilities would occur. This would be hugely a defining factor for humanoid reproduction capabilities.

- Amazon.Com. (2012, September 2). RapMan ultimate dual head 3D printer with turboCAD deluxe 1. Retrieved September 5, 2012 from http://www.amazon.com/RapMan-Ultimate-3D-Printer-TurboCAD/dp/B005OSFP0I/ref=sr_1_2?s=pc&ie=UTF8&qid=1346805094&sr=1-2&keywords=3d+printer

- Anthony, S. (2012, January 25). What is 3D printing? Retrieved on September 5, 2012 from http://www.extremetech.com/extreme/115503-what-is-3d-printing

- Atala, A. (2011). TED: Printing a human kidney [Video file]. Video posted to http:/www.ted.com/talks/anthony_atala_printing_a_human_kidney.html

- Bone, A. (2012, May 26). Game changer - 3-D printing. Waikato Times . Retrieved September 3, 2012 from http://www.stuff.co.nz/waikato-times/life-style/people/6987064/ Game-changer-3-D-printing .

- Broadening the impact of pictures. (n.d.). Retrieved September 3, 2012 from http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Impact_of_Pictures.htm .

- Castle Island. (2012, March 8). Comparison chart of all 3D printer choices for approximately $20,000 or less. Retrieved September 6, 2012 from h ttp://www.additive3d.com/3dpr_cht.htm

- Computer Aided Design. (n.d.). Retrieved September 5, 2012 from Wikipedia: http:/en.wikipedia.org/wiki/Computer-aided_design.

- Daneman, M. (2012, July 11). Kodak reorganizes, again, on its way out of bankruptcy. USA Today . Retrieved September 3, 2012 from http://www.usatoday.com/money/ industries/manufacturing/story/2012-07-11/kodak-reorganization/56149400/1 .

- Dent, S. (2012, August 24). TangiBot manufactures ethics controversy by replicating open-source Makerbot 3D printer . Retrieved September 6, 2012 from http://www.engadget.com/2012/08/24/tangibot-kickstarter-makerbot-clone/.

- Devijver, S. (2011). Reprap: Building your own 3D printer. Retrieved September 6, 2012 from http://reprapbook.appspot.com/.

- District of Columbia v. Heller. (2008). Retrieved September 3, 2012 from http://www.lawnix.com/cases/dc-heller.html

- Gross, G. (2010, November 21). Computer World: 3D printing a minefield of legal challenges. Retrieved August 13, 2012 from http://computerworld.co.nz/news.nsf/technology/3d-printing-a-minefield-of-legal-challenges .

- Harouni, L. (2011, November 1). TED: A primer on 3D printing [Video file]. Video posted to http://www.ted.com/talks/lang/en/lisa_harouni_a_primer_on_3d_printing.html .

- History of Kodak. (n.d.). Retrieved September 3, 2012 from http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Imaging-_the_basics.htm .

- Kelly, R. (2012, August 26). The next battle for internet freedom could be over 3D printing . Retrieved September 6, 2012 from http://techcrunch.com/2012/08/26/the-next-battle-for-internet-freedom-could-be-over-3d-printing/.

- Material science. (n.d.). Retrieved September 3, 2012, from http://www.kodak.com/ek/US/en/Material_Science.htm.

- Medical Devices [Fact sheet]. (2009, August 7). Retrieved September 3, 2012 from http://www.fda.gov/MedicalDevices/ProductsandMedicalProcedures/ DeviceApprovalsandClearances/Recently-ApprovedDevices/ucm079437.htm

- Milestones - chronology. (n.d.). Retrieved September 3, 2012 from http://www.kodak.com/ek/US/en/Our_Company/History_of_Kodak/Milestones_chronology/Milestones-_chronology.htm .

- Mosbergen, D. (2012, August 8). Michael Guslick, amateur gunsmith, claims to have used 3D printer to make functional semi automatic AR-15 rifle at home. Retrieved September 6, 2012 from http://www.huffingtonpost.com/2012/08/08/man-3d-printer-rifle_n_1753513.html.

- Objet: About US, A global 3D printing provider (n.d.). Retrieved on September 6, 2012 from http://objet.com/company/about.

- Olson, P. (2012, July 7). Airbus Explores Building Planes With Giant 3D Printers. Retrieved September 7, 2012 from http://www.forbes.com/sites/parmyolson/2012/07/11/airbus-explores-a-future-where-planes-are-built-with-giant-3d-printers/

- Printed image. (n.d.). Retrieved September 3, 2012 from http://www.kodak.com/ek/US/en/Printed_Image.htm.

- RepRap. (2012, August 1). Retrieved September 5, 2012 from Wikipedia: http://www.reprap.org/wiki/RepRap.

- Ryan, J. (2012, March 10). Crowd Manufacturing. Retrieved September 7, 2012 from http://johnnyryan.wordpress.com/2012/03/10/crowdmanufacturing/#more-2213.

- Richmond, S. (2011, July 28). 3D printing: the technology that could re-shape the world. Retrieved September 6, 2012 from http://www.telegraph.co.uk/technology/news/8666516/3D-printing-the-technology-that-could-re-shape-the-world.html.

- Stadlmann, K. (2011, October 7). TED: The world’s smallest 3D printer [Video file]. Video posted to http://www.ted.com/talks/lang/en/klaus_stadlmann_the_world_s_smallest_3d_printer.html.

- Stratasys. (2002). The competitive advantages of 3D printing. [Brochure]. Eden Prairie, MN 55344-2020 U.S.A.

- Tamarian, D. (2012, June 26). 9 Benefits of 3D Printing. Retrieved September 7, 2012 from http://augmentedtomorrow.com/9-benefits-3d-printing/ .

- UP! Personal portable 3D printer (2012). Retrieved September 6, 2012 from http://pp3dp.com/.

- Yu, R. (2012, August 6). 3D Printer: 3D Printers, obsolete firearm supply controls and the right to build self- defence weapons. Retrieved September 6, 2012 from http://www.3dprinter.net/3d-printers-obsolete- firearm-controls-and-the-law.

- 3D printing. (2012). Retrieved September 7, 2012, from Wikipedia: